Boning Aid

|

|

|

A TECHNOLOGICAL ENHANCEMENT

OF BEEF QUARTER BONING PRODUCTIVITY

Traditional beef quarter boning techniques have largely remained unchanged for decades. Recent technological advances have allowed the development of the PECO Boning Aid system.

The combined effect of more heavily muscled carcases, the desire for better meat hygiene and more uniform meat cut shapes, places greater pressure on the Boners.

This can lead to a greater risk of tendon injury. The PECO Boning Aids are specifically designed to reduce the effort required from the Boner and hence reduce the risk of tendon injury.

The assistance provided by the PECO Boning Aid allows for the potential of increased boning yields due to cleaner bones and improved, more consistent meat cut shapes.

Introducing the PECO Boning Aids to a conventional quarter boning room can realise the financial benefits of reduced strain injuries and improved meat yields.

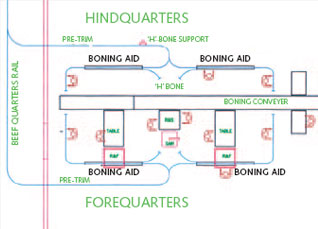

TYPICAL BONING AID SYSTEM INSTALLATION

The layout (shown opposite) is an example of a PECO Boning Aid system in a typical boning room. For the purpose of illustration, four PECO Boning Aids have been shown on the layout in order to bone 200+ beef bodies per 71/2 hour shift. This also means that each machine can be dedicated to specific boning tasks. That is to say, one PECO Boning Aid would be used for each of the left hind, right hind, left fore and right forequarters. For smaller abattoirs the PECO Boning Aid would be configured to process both the left hand and right hand quarters and/or alternately fore and hindquarters.

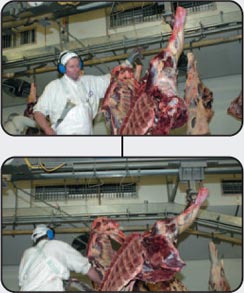

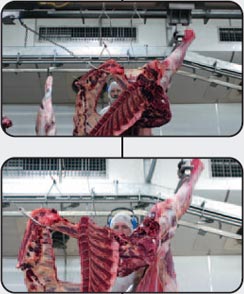

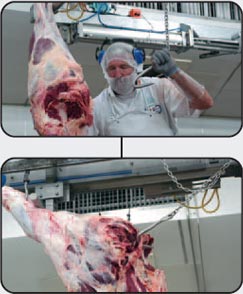

FOREQUARTERSForequarters are pre-trimmed in the room prior to being moved to one of the two forequarter PECO Boning Aids. The rib cage is attached to a meat hook on a skid and restrained as the boning aid moves the shank along the rail. The forequarter meat is thus separated from the rib cage. |

The rib cage is released and directed by rail to a bone trim station. Alternatively, the intercostal meat can be removed by the PECO Boning Aid as part of the forequarter meat. HINDQUARTERSThe hindquarters pass along the pre-trim rail to a "H" bone support device, where the ball of the femur is separated from its socket on the pelvis, and some preliminary opening up carried out to allow for the PECO Boning Aid to perform its task. |

|

|

| FOREQUARTER PROCEDURE | HINDQUARTER PROCEDURE |

|

|

THE BENEFITS OF BONING AIDS

There are a number of potential benefits obtainable by using PECO Boning Aids. The aid can be likened to a tradesman's tool in that the benefits are limited only by his skill and innovation.

There are a number of potential benefits obtainable by using PECO Boning Aids. The aid can be likened to a tradesman's tool in that the benefits are limited only by his skill and innovation.

Compared with conventional quarter boning systems the potential benefits and opportunities claimed by users of PECO Boning Aids are:

Increased Meat Yields

Production operations have suggested increased meat yields of up to one per cent are achievable.

Reduced Skill Levels for Boners

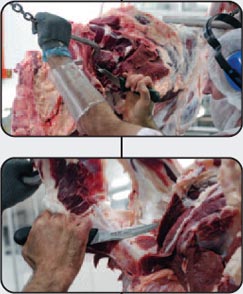

The PECO Boning Aids can be used in a similar way to a hide puller, where the operator only performs light tasks releasing tight spots with a knife. Skill is still required but is less than that needed to follow the contours of all the various bones in conventional quarter boning.

Suitable for Cold, Warm & Hot Boning

As the PECO Boning Aids are intended to provide the force necessary to allow easy access for the Boner's knife, the meat can be much colder than the traditional minimum of 7ºC. The lower temperature available by using PECO Boning Aids provides more stable meat for good shape retention during subsequent trimming. The force settings on the PECO Boning Aids can be adjusted to suit the meat temperature and fat hardness.

Reduced Manual Effort by Boners

The Boner does not need to apply manual force to hold the rib cage apart while boning the forequarter. As the PECO Boning Aids provide the forces usually provided by manual labour, the Boners do not become as tired during the day.

More Accurate Cutting Lines

The PECO Boning Aids allow larger portions of meat to be removed in one piece. In the case of the fore quarter, the bulk of the meat is released in one operation where it is transferred to a table. From this table it is broken down into manageable individual cuts, along the correct cutting lines.

Less Double Cutting of Meat

The use of PECO Boning Aids greatly assists the Boner to access his knife into the interface between the expensive meat alongside the spine and the spine. This leads to much cleaner cutting lines with reduced second

cutting common with manual boning.

Fewer Tendon Strain Injuries for Boners

Because the Boners no longer have to fight their knife through thick sections of hard meat with frequent turning of the knife to follow the contours of the bones, fewer strain injuries are experienced.

Fewer Knife Injuries

As the Boners normally only need to apply light pressure to their knives, fewer knife injuries will result.

Improved Boner Productivity

The reduced Boner fatigue and injuries facilitated by the PECO Boning Aid allows potential for extended working time with improved productivity from the rail Boners.

The working life of the Boner can be enhanced with savings in training and down time. The method in which the PECO Boning Aids are used will reflect in the extent of the benefits to be gained and which items show the greatest benefit.

MECHANISM DESCRIPTION

| "PECO" Beef Quarter Boning Aids are designed to support the optimisation of beef body fore & hindquarter boning. |

|

|

Construction Each PECO Boning Aid comprises a robust frame in which is mounted a carriage. From this carriage is mounted the boning aid separator arm ("pushing device"). The separator arm carriage is lineally traversed forwards and backwards within the PECO Boning Aid frame. The transmission to the separator arm carriage is provided with adjustable constant torque from low (stall) to base speed. In this manner the pressure (push) applied to the carcase quarter is controlled to suit the requirements of the Boner. Operation To optimise boning control and minimise total cycle time the transmission to the separator arm carriage is provided with three speed settings, namely a "high" and "low" speed setting each of which is speed limited (but adjustable) and provides constant torque (the value of which is also adjustable), and a "return" speed setting which effects maximum acceleration for the return of the carriage to "home" position. Typically the carriage motion is commenced on high speed from "home" until engagement with the carcase quarter whereupon, as determined by the Boner, the carriage may be switched to low speed to support intricate or difficult boning and/or the skill of the Boner. Upon completion of boning the carriage continues its forward travel to the end of the PECO Boning Aid from where it automatically returns to "home" position. |

Control Typically the carriage transmission torque values are set differently for the low and high speed settings in order to provide optimum support to the Boner for both high quality meat removal and timely boning performancePull cords are provided to allow the Operator to conveniently initiate the cycle at the start of the boning operation and to select the appropriate speed/torque setting through the cycle. Selection and tuning adjustment of the torque values is effected by means of an Operator Control Panel conveniently located to the Boner. Through the Master Control Panel, which is typically located within the Boning Room Supervisor's Office, different high/low values can be entered and saved for various carcase types e.g. Prime, Bull, Manufacturing. Via the Operator Control Panel the Boner switches the PECO Boning Aid to the carcase type being processed and thereby the appropriate separator arm force values. Hygiene Compliance Overall, the design and manufacture of PECO Boning Aids is in compliance with "The New Zealand Meat Industry Hygiene Council Industry Standard 2 (IS2): Design and Construction". They are of hygienic and non corrosive construction, waterproof and able to be fully hosed down. Because of their design there is no dirt fallout onto the meat. Reliability They have been successfully Industry proven since 1995, are silent in operation and have proven to be very reliable in their critical application with a minimal maintenance requirement. |

|

|

HISTORY

|

The first PECO Boning Aids were developed and commissioned in 1995 for an abattoir processing Feed Lot Cattle beef subjected to a 48 hour room chill before boning.

Carcass chill regimes range from 48 hours through to warm and hot boning.

|