Shamrock Rapid™ Wrapper

Introducing the new generation SHAMROCK RAPID™ WRAPPER. It is the ideal machine for any newspaper or magazine distribution operation wanting to enjoy the benefits of automatically rolling and wrapping publications in plastic film.

The machine was conceived and developed in 1987 at New Zealand's Christchurch Press Co and is now installed at several other Fairfax subsidiaries and independent publishers.

| BENEFITS The benefits to having a SHAMROCK RAPID™ WRAPPER include: |

|

| Customer Satisfaction |

Your publication is assured of being delivered to your customer dry, clean, free of tears or abrasion marks and with all inserts secure within. The plastic film allows easy removal of the wrapping by the customer |

| Increased Productivity |

1,800 units approx. per hour (dependent upon the skill of the operator) thereby reducing the time taken to prepare your publication for delivery and allowing earlier circulation by runners |

| Labour Savings | Intensive hand wrapping is a thing of the past |

| Consumable Cost Saving |

Use of plastic film is very cost effective, especially compared with waxed wrapping paper and even plastic bags |

| Versatility | Model M4SC: 14-56 pages (nominally) and up to 425mm in width Model M5LC-F: 38-200 pages (nominally) and up to 425mm in width |

| Consistency and Quality |

Avoids inconsistent results associated with hand wrapping |

| Runner Satisfaction |

The SHAMROCK RAPID™ WRAPPER result is a delight for the Runner to stack and distribute |

| Ease of Operation |

Operator friendly and can be used by anyone after training |

| Silent Operation |

A special feature of the new generation machine |

| Compact | Upright design means minimal floor area used as well as ease of portability for off-line wrapping when required |

| Modular Design | Allows easy integration with accessories and other equipment |

| Reliability | Industry proven technology following many years of development since 1987. Operation is tamper protected |

| Safety | To comply with occupational safety and health requirements the machine is appropriately guarded and becomes fully de-energised when electrical supply is terminated |

| Low Maintenance |

Robust construction, superior roller design, sealed bearings and other superior features keeps maintenance times to a minimum. Utilisation of standard commercial parts wherever possible minimises maintenance inventory requirements and costs |

| Customer Satisfaction |

A special feature of the new generation machine allows the operator to select from three size settings (small/medium/large) to control tightness of the roll to avoid annoying curl in the unwrapped publication |

"The SHAMROCK RAPID™ WRAPPER offers an immediate and substantial return on investment with significant labour and consumable savings. In today's highly competitive environment can you afford not to make this smart investment?"

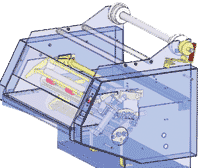

HERE'S HOW IT WORKS

The newspaper or magazine is placed upon the tray at the front of the SHAMROCK RAPID™ Wrapper and presented squarely to the in-feed zone. Upon each presentation the machine automatically draws-in the newspaper/magazine, rolls and wraps it. The wrapper product is automatically discharged from beneath the SHAMROCK RAPID™ Wrapper following which the cycle is ready to be repeated.

The machine's automatic cycle time is rapid.

By attentively synchronising their newspaper/magazine feeding with the machine cycle the operator optimises the hourly throughput capacity they achieve.

- A particular feature of the machine is that once wrapped the publisher's name on the top of the publication is always visible - supports product branding and advertising.

- The machines use plastic film of only 15 micron thickness which minimises consumable cost and environmental impact at disposal.

- Whilst securely wrapping the publication, during application of the plastic wrapping film, the machine applies a separation strip to make the customer's removal of the wrapping film very easy.

Specifications

| Machine Size: | Width 800mm, Length 600mm, Height 600mm |

| Machine Mass: | 60kg nominal |

| Machine Colour: | 'Sky Blue' (unless otherwise requested) |

| Standard Size (Optional): | Width 800mm, Length 600mm, Height 1,0000mm |

Services Required

| Electricity: | 230-240 volt, 50 Hertz, single phase (preferably with 'spike protection' to prevent damage to the machine's electronics) |

| Compressed Air: | A clean, lubricated, compressed air supply at 6.5 to 9.0 bar (90 to 130psi) is required, the minimum pressure being dependent upon the newspaper/magazine size and stiffness. Nominal air consumption is 35 Nl/min (1.2scfm) |

Consumable Specification

The machine has been designed to operate with plastic film type EXVMD500ALC 500/1500 VALUE DL as supplied by Integrated Packing Limited.

The film has been specifically developed for this application. Use of any other film specification is not recommended as the machine's performance is likely to be adversely affected and the machine warranty deemed null and void.

Accessories (Optional)

- Mounting stand and collection bin

- Electronic Counter

Accessories in Development

- Automatic Hopper Feeder Module

- Discharge Conveyor Module

Manual

Supplied with the SHAMROCK RAPID™ WRAPPER is a comprehensive Operation/Maintenance manual.